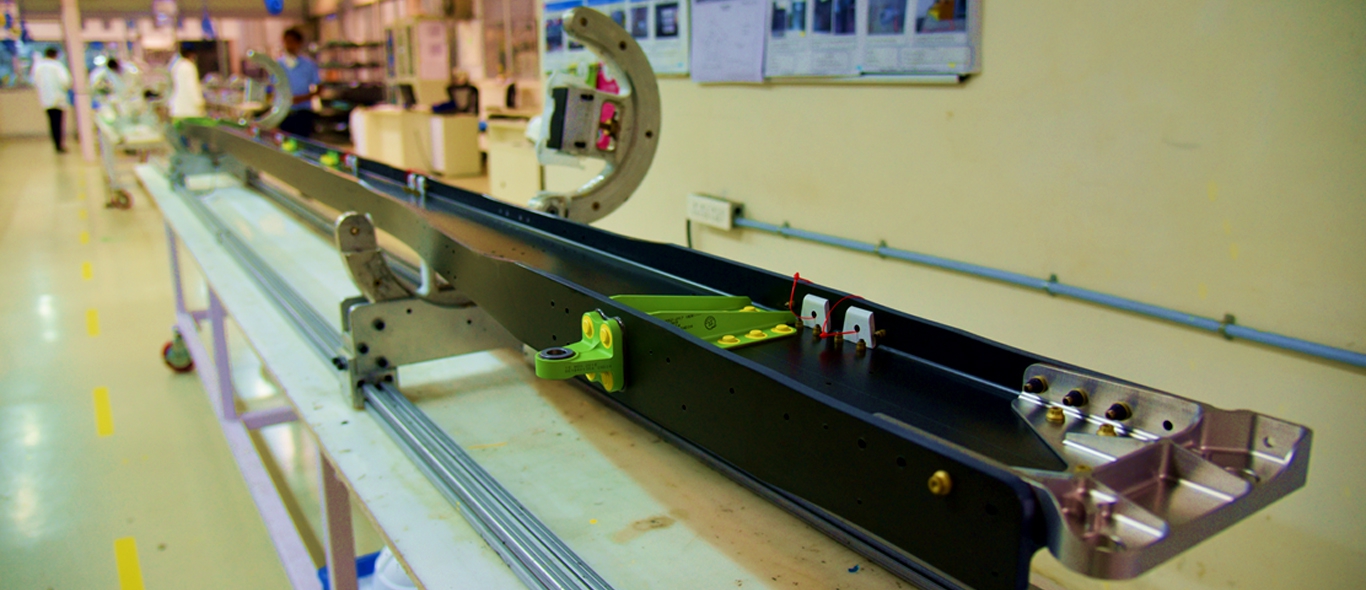

LAYUP PROCESSES - PREPREG

With over 3000 metre square of clean room capabilities, with state of the art laser projection system and CNC ply-cutters Tata Advanced Systems executes manufacture of critical components for the world's aerospace composite requirements. Our global partners have recognized our quality and delivery performance on advanced composite floor beams, tail cone, wing spars, ailerons, control surfaces and panels manufactured on the single-piece flow line at our facility.

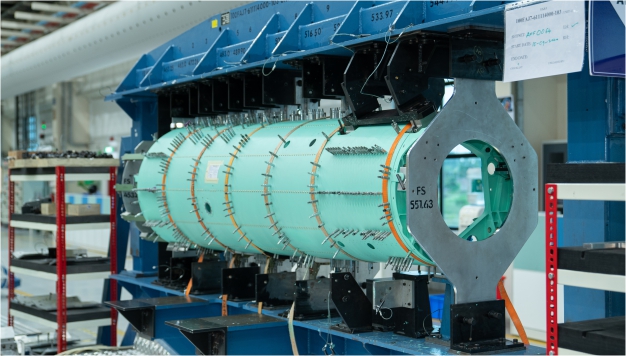

CO-CURING AND BONDING

We are proficient at design and development for consolidating skin, spar and mid ribs co-curing and have performed the processes for notable commercial and defence programs centered on weight and assembly effort optimisation on fin, rudders and fuselage assemblies.Our commitment to advanced technologies with aerospace majors such as National Aeronautics Laboratory-India, Indian Space Research Organisations and international partnerships for catering to the design concurrent engineer, manufacture of aircraft aerostructures, engine components, to name a few.

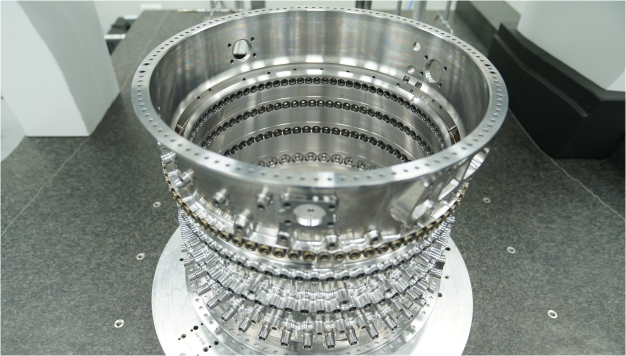

QUALITY ASSURANCE & TESTING

In-house, self-reliant OEM certified quality assurance ecosystem is in place to cater to stringent international customer requirements. Our test capabilities ranges from 10-Axis Through Transmission Equipment to a wide range of Pulse Echo test capabilities including C-Scan systems and thermographic test capabilities. We have large bed contour measuring equipment in place for ultra-precision. Our world class testing infrastructure is complemented with globally certified NDT Level-3 to Level-1 specialists.

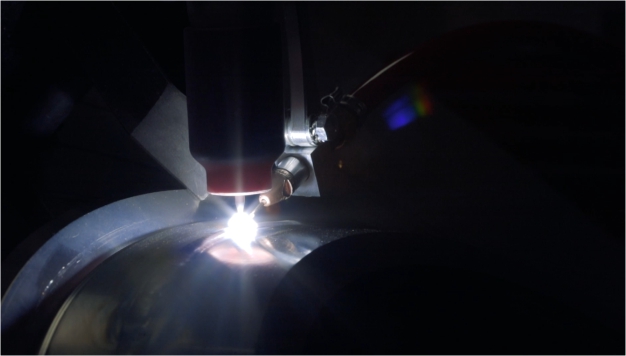

SPECIAL PROCESSES

With an intent to provide turnkey composite solutions to our global customers along with a self sustained composite component manufacturing, Tata Advanced Systems has established a range of qualified special process capabilities driven by aircraft OEMs' needs. These capabilities include acoustic drilling, paint booth, advanced reticulation, a suite of surface preparation techniques and core processing to name a few.